Dateline: 20 August 2007

Updated: 30 June 2017

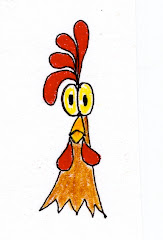

Years ago, I built myself a remarkably effective mechanical chicken plucker. I named it the Whizbang Plucker. Then I wrote a book telling others how to easily build their own inexpensive Whizbang Plucker. People bought the book. They built their own plucker. They were delighted with what the machine did for them.

Simply put, a Whizbang Plucker makes chicken plucking fun. I’m very serious when I tell you that.

Thousands of copies of the book have now been sold. Thousands of Whizbang Pluckers are now hard at work all across America. Homemade Whizbang Pluckers are also plucking chickens in at least a dozen other countries. It is an amazing thing. It is a Whizbang revolution.

What does this mean? It means that more and more people are once again raising wholesome food for themselves, independent of the Industrial Providers. Where will it lead? I like to think it will lead to a Whizbang Plucker in every backyard, and a home-raised chicken in every self-sufficient citizen’s pot.

Bearing that in mind, many people have e-mailed me over the years with questions about the Whizbang Plucker. I have decided to assemble many of the questions, and my answers, here. If your Whizbang question is not answered here, please send me an e-mail (Herrick@PlanetWhizbang.com). I will do my best to answer it.

Best Whizbang Wishes,

Herrick Kimball

Update

June 2017

7 comments:

Herrick,

this all sounds like great stuff to a guy like me. I've plucked probably a hundred pheasants in the last couple of years by hand, and also with a drill mounted plucker. You mention that bruising doesn't occur if the birds have been bled. Do you have experience with birds that have not been bled out? When my buddies have pheasants for me, I tell them to leave them intact and cool them down. I usually age them for about a week or two at forty degrees, then process them. I don't think I can get these guys to bleed them out, in the field. So, I wonder if bruising would be a concern for this application. Thanks!

Hey Herick ,...Hope your well... want to build W.B.C.P.

However not ready yet ... When I am ready , I want to

buy your shabang kit ... When I do , would you please

write down adaptations neded and sell me the correct

fingers & quantity of them so it will also pluck quail ?

I really enjoy all your writings and do not want to have to

use any other vendor or plans but yours ...

If built do you believe it would work on quial , chickens, turkey , and ducks ? Would it perform & last like the

standard W . B . Plucker ? Or are they just two seperate

machines ? It would be great if I could do it all with one

machine .... However if quality would suffer , would not

want to mess with the great machine . Please advise ...

Thank You Tim C . Franklin. , Tn.

Hi Tim,

A Whizbang plucker made with lots of fingers so it can pluck quail will pluck other birds just fine. You don't need two separate machines. I say that based on what I've been told, not on personal experience.

Unfortunately, I've never plucked quail and I can't advise you on the specifics of building a quail plucker, other than that you need a lot of fingers and they need to be of the softest kind. My standard plucker parts "shebang" kit does not have a featherplate that is drilled for a lot of fingers.

I will ask about making a Whizbang quail plucker at the Yahoo discussion group, WhizbangChickenPluckers. There are a few thousand members there and hopefully they can provide some good advice on the subject.

Otherwise, you may want to buy a Featherman quail plucker.

Best wishes,

Herrick Kimball

I have a 2 3/4" drive pulley with 5/8" bore. Would using a 16" driven pulley work? Or would I be better off getting the 2 1/2" drive pulley and using a 15" driven pulley?

Janice,

I recommend a 16" driven pulley with a 2.5" drive pulley. But I'm sure your 2.75" drive pulley with a 16" pulley will work just fine.

I have a 1.5 hp, 3450 rpm motor from an old Delta shop grade table saw. Is that motor to much umph for a Whizbang?

What are the hole dimensions for the feather plate I know the whole size is 3/4 but I was curious about the layout of the holes on the plate dimensions for the feather plate?

Post a Comment