Dateline: 22 November 2013

|

| Kate and John Suscovich |

There are many aspiring small-scale agripreneurs like John Suscovich in the local-food, sustainable, "young-farmer movement" and it is great to see.

John, however, may be a bit different than most because he has some better-than-average marketing skills, especially when it comes to the internet. His web site, Foodcyclist.com is an ambitious effort that reflects John's focus and creativity. He has a farm blog, and a farm podcast, and has produced numerous YouTube videos.

Beyond that, if you watch some of John's YouTube videos you'll see that he is an affable guy, which is another plus when it comes to starting an agripreneurial venture.

John also has a web site called Farm Marketing Solutions, which is dedicated to helping start-up farmers better market themselves and their farms. If I were an aspiring young farmer, I would learn everything I could from John—from his example, and from his marketing savvy. With that in mind, check out John's YouTube movie telling How To Start A Farm With No Money

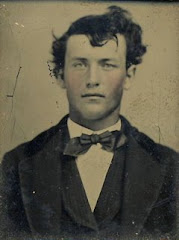

Suscovich Chicken Tractors

|

| Those are some nice chicken tractors, eh? |

I've been there, especially when it comes to marketing a how-to book. I know how much work it is and I know how I appreciate people who have taken an interest in my books along the way and helped me by telling others about them on their blogs.

Some bloggers are so focused on making money with affiliate links, advertising, and selling their own products that they aren't really interested in helping someone else, unless they can make money at it. That's not me. I don't have affiliate links, I don't have any advertising (unless it's for my own products), and I am delighted to use this blog to help anyone with a useful, "down-to-earth" product or service that I think my readers will enjoy knowing about.

So I checked out the complimentary copy of John's new "stress-free" Chicken Tractor E-Book, and I must say that I really like his design. Fact is, I like it so much I plan to make one (at least one).

John's chicken tractors are made to fit on the 6' x 12' trailer he uses to haul things on his farm. The tractor footprint is just about 60 square feet. He built 12 tractors for his chicken operation and puts 30 chickens in each tractor.

The structures are made with pressure treated lumber frames, 2' high on the sides. The roof is made of 3/4" electrical conduit "rafters" covered with a tarp. The door on one end allows people to walk into the tractor.That is a great feature. The chicken feeders and waterers are suspended and travel with the tractor as it is moved.

The tractors are moved by hand, pulling them with a rope on one end. Moving is made easy by two wheels that are temporarily slipped over a protruding bolt at the other end.

John uses his chicken tractors only for raising broilers, but he says they could be outfitted with nesting boxes for a few egg-layers. They can also be covered with plastic and be used as a small greenhouse. I like that idea.

John's e-book has a material cost breakdown and he figures each tractor has around $160 in materials in it. He makes it clear that he chose to use high quality (pressure treated) lumber, but the tractors can be made for less using other materials.

The e-book is 31 pages long. It has clear specifications for each component. It has lots of photos. It has links to YouTube movies that better explain certain things. It has additional information about the feeders and waterers he made, and how he raises his chickens. The book has a nice overall appearance.

On the downside, the tractor design requires a conduit bender to get the proper bend in the "rafters"…. and the know-how to use the bender. That's probably a stumbling block to a lot of people. The plan also calls for half-lap joints in the wood frame. It is possible to mortise the wood for these joints with an electric skillsaw and a chisel, but a dado blade in a radial arm saw is a much better tool. So, if you follow John's plan exactly, you will need some equipment that most people don't have—or you will need a friend with the equipment to help you.

Like I mentioned, I intend to make one of John's nifty chicken tractors, but I haven't done so yet. Therefore I can't tell you how well the tractor goes together. Chances are, when I get to making one, I will modify the design to some degree. One modification I'm pretty sure I'll make is to add some sort of long diagonal brace on the 2' high sides. A long brace would give the structure a whole lot more racking strength. And I think I would like to have the tarp on the roof come all the way down over the sides. But the finished product will retain the same overall look, and all the best design features.

John's book sells for $19.95. If you Listen To This Podcast (at least the first few minutes) John gives a discount code you can use to get the book for 25% less. Discount or not, I think the book is worth the cost if you want to make yourself a nifty looking chicken tractor with some real nice features.

By the way, John Suscovich also has an affiliate program for anyone who wants to sell his e-book at their blog or web site. If someone clicks through and buys a copy, you get a commission. I considered doing this but I decided against it. The guy is working hard, providing worthwhile products, and trying to support his family. I'd like to see him get the most from every book he sells.

24 comments:

Very attractive...but alas our local raccoons and foxes would see this as a travelling buffet..

I like the design, simple and effective though I would replace the low chicken wire with the metal lath material that comes in sheets, it is very strong yet you can see through it. I might even put a battery powered fence charger on it as we are overrun with coyotes, coons, fox and even bob cats. A design like this can be modified easily!

Hi Kathi,

Thanks for the comment. Any kind of "tractor" full of chickens is a temptation to various predators. John discusses this in his book and has a picture of a bobcat by one of his tractors. Any varmint would have to work very hard to get through a well-wired tractor. 1/2" hardware cloth can be put on the lower 2' of frame for the best defense. I've lost chicks to a small critter getting through a gap under the frame.

Sunnybrook Farm,

Metal lath would do it. A Strand of electric fencing around the tractors would also make a big difference. This is mentioned in the e-book.

Hi Herrick,

Interesting - I've got his webpage bookmarked for further reading. Thanks -

Well I just got my clothespins. Ha - tried to puzzle out the best way to assemble without looking at your directions. Well that lasted about 1 minute with a busted fingernail to boot (not really broke - just bent…) . Once I looked at your assembly picture I saw my error and had them together in a breeze. I reckon you must have some sort of tool to quickly assemble the hundreds you've sold. Either you made a mistake or I lucked out because the wood “pins” needed no sanding whatsoever. I'll use them indoors for model building and light clamping. Very fine product and I think a bargain. They’ll last forever indoors and a long time outdoors if given a modicum of protection from sunlight and rain.

Kind Regards,

Muns

P.S. Interesting to note there seemed to be a variance in spring tension when assembling. None were loose and all clamp extremely very well but I thought I felt a definite difference in tension in a few springs. Possibly a point of discussion when you order your next batch.

We're thinking of doing a few broilers this spring. This tractor would do nicely. Thanks for the link.

Muns,

Thanks for the positive feedback on the clothespins. I do have a clever clothespin assembly tool that a friend of mine invented. You are right that there is some very small variation in the springs and I think that is just the way it is with an inexpensive torsion spring. I watched the cnc spring-making machine make some of the springs. It is a technological wonder. Then they go on a conveyor through an oven for heat treatement and the coil tightens up. I think the minor variation happens during the heat treatment .

Cynthia,

Raising a few broilers will be a great family project. It's a good feeling to have your own homegrown chickens in the freezer.

Thank you for this post. It is very inspiring to me, as both my parents were raised on family farms, but got "careers" and I ended up on a "career" path too. My dad went back to farming 30 years ago and now doing the same is all I can think about.I have debt and other obstacles but I know with determination and some sacrifice it can be done.

Hi Sonja,

I'm glad to know this post has been inspiring for you. I wish you the very best as you pursue your farming dream.

Very nice, and it's so refreshing to hear about young people getting "the light" I will be checking out that book for sure. I hope to have chickens this spring, and had considered a tractor too.

I got my clothespins together too, and I LOVE THEM!

You see, I'm from the "old school" and even the ones I remember from my youth, were never this good. I had to do almost no sanding either, they turned out perfect, and I just know that they will last a very long time. I am really thrilled with them.

I will be purchasing more too.

Shheila—

Thanks very much for the great feedback on the clothespins. I so glad that you are happy with them.

Herrick,

I try not to be a Salatinite and I believe (as I think Joel does too) that his ideas are just waiting to be improved upon by the next generation. That said, there seems to be some design issues with this one from my own experience (I've raised several hundred chickens over the last few years). I would like your thoughts on them:

1. Although it seems nice to be able to walk in the tractor, this is rarely necessary on a daily or even weekly basis. At the same time, it seems like it leave the chickens exposed to a lot more of the elements. This is good if it is a warm sunny day, bad if it is a wet cold rain.

2. The "standard" Salatin tractor is 10x12, or 120 square feet, and holds approximately 70+ chickens. This one is less then half the size and holds less than half the chickens. For commercial application, I am moving twice as many tractors (twice as much time) for the same number of chickens.

3. I lost several chickens from paws through the chicken wire before adding hardware cloth to the bottom 12". I can only imagine that would be a requirement (as you mention).

4. It seems like he has traded out the weight of the metal roofing for the weight of the hefty structure. Only time will tell if this is a worthwhile trade.

All in all, I would have liked to have seen several years of testing before all the marketing. If he changes the design or continues to tweak (as we all will do), everything will need to be updated. My initial thought is that it is a good family tractor for small batches each year and in that sense, is a lot more fun than the Salatin tractor.

Thanks for exposing me to new ideas!

Hi Warren,

That is a good analysis. Thanks for posting it. I still plan to build something akin to the design, but I'm not a commercial poultry raiser. I think that walking into the cage would be an especially nice feature when it comes time to round the birds up for "processing."

Herrick, I accidently duplicated some items on an order. But I can't find an email link to contact you so I'm posting here. Please tell me how to contact you concerning this.

Debbie Kirkland

I recently bought the plans and built this tractor. I am two weeks out from harvesting my first batch of chickens In it. I really like the height compared to other designs and I actually do go inside pretty often. It may sound crazy but sometimes I hang out inside with them and observe how long they eat and drink water.

I use a 5 gal bucket to fill the water bucket so I have to do this from the inside. I found that I can feed them from the door by lifting one side of the PVC feeder and letting it slide to the other end until it fills. Then I can move the tractor since they follow the feed as I'm moving it and most of them move along good although a few are getting a little slow the biggest they get. I then can go in with the water and walk on fresh grass instead of a buch of poop.

I highly recommend the design. My biggest problem was bending the conduit which was the last thing I expected to have trouble with. I finally figured out what to do with the help of an online conduit bending calculator I found online.

I read somewhere that you can use these for rabbits too.

They said to add chicken wire to the bottom part of the cage so the rabbits can't dig under and get out. When I get my little farm going I plan on doing something like this for both rabbits and chickens.

Great idea!

There is a chapter in John's book about predators. Is good to say that an electric string around the group of chicken tractor is necessary.

Needless to say how right you are regarding the dream of our young generation. They are really passionate about some good-paying job to build their future career and for a dreamy luxurious life. But if we all hanker after high paid job, what will be the other sectors that also are essential for our life. Just discovered your well-valued post and was impressed how you bring the agriculture section into an important focus with huge possibilities. Glad to know about John Suscovich and his agriculture passion. It might be the great inspiration of our your people. Thanks for your fantastic job. My browsing story was to learn about Roofers Folsom but this was made me so so happy.

Thank you for writing this! The information was presented in a very digestible way, which I really appreciated. It’s not always easy to find such concise and useful resources on this subject. Great work!

waterproof tarpaulin

Very Informative Blog !!!

tarpaulin

This was a fantastic read!

Decking Tiles

I love the wonderful way you separated this! It's dependably perfect to see new bits of knowledge on [Tarpaulins UK]. Can hardly hold on to evaluate your ideas!

Its one of the best blog i have came through.

Tarpaulin

Post a Comment