Dateline: 12 April 2016

|

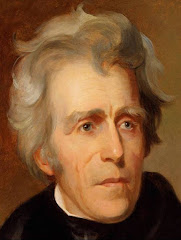

| There it is! The Whizbang Toe-Tapper Faucet Switch. |

It’s hard to believe that two years have gone by since I unveiled my Whizbang Toe-Tapper faucet switch here! Many of you reading this (97 of you to be precise) bought one of the 100 prototype Toe-Tappers I offered for sale at that time.

For readers who are not familiar with the Toe-Tapper, it is a hands-free way to control the water in an outdoor sink (don't miss the video below). Just tap the switch with your foot to turn the water on and off. Or, if you mount the switch at thigh or hip height, you can just give it a bump to switch the water on and off.

The Toe-Tapper frees up both hands to focus on the work that needs to be done. I developed the Toe-Tapper specifically to help with the task of backyard poultry processing, but it is now permanently attached to my outdoor summer sink.

Based on my own experience with the Toe-Tapper, and the feedback I’ve gotten from the many beta-testers out there, I’m moving ahead with plans to launch a Toe-Tapper web site. I’ll be selling specifications for people who want to make their own inexpensive Toe-Tapper, along with parts kits, and already-made Tappers. The web site is at www.WhizbangToe-Tapper.com

With all of that in mind, the specifications are now in PDF format and are available for download. The 7-page specifications package can be purchased now at this link: PDF Specifications For Making Your Own Planet Whizbang Toe-Tapper Faucet Switch.

The Toe-Tapper is relatively simple to make, and I’m hoping that most people will decide to make their own. This is an economical alternative to buying and already-made Toe-Tapper, which will sell for quite a bit more than the $21.95 that I sold those first 100 prototypes for.

If you would like to see the Toe-Tapper in action, please check out the video below. It shows my own outdoor sink (the “sink of my dreams”) with a Toe-Tapper positioned at thigh height. I think it’s a more convenient location than on the ground.

6 comments:

Happy birthday Toe Tapper! #1 is still going great. We process all our chickens/turkeys/ducks/ fish/and squid down, at the barn but i am just about ready to get myself into the outdoor kitchen business closer to the house, like on the back patio.

Down at the barn we have a Rinnai instant on water heater hooked up to the toe-tapper for working on those turkeys and boning hogs heads to get the guanciali in November/December. We can regulate the water temp from 60 to 140 degrees.

Two pigs just arrived yesterday and right away my youngest son named them Prosciutto, and Pancetta. He has two 25 lb Prosciuttos hanging in a small soda cooler refrigerator. Has to be there for two years at a certain temp and humidity. Hope I live long enough to get a bite or two!

I have shown your idea book to three or four folks and they were impressed.

Hope they will all get one on order. Also a few folks want to rent the apple press and grinder. Looks like I've generated myself some competition in the apple picking venue!

Good luck with the toe-tapper sale. Best Regards, Everett

Has nothing to do with your post. I just wanted to say that I enjoyed seeing one of your articles on The Abbeville Institute's website.

Everett—

It's nice to know that prototype Toe-Tapper #001 is getting a good workout, and still doing the job after two years.

I think a lot of people bought one of the prototypes because they recognized it was a good idea (and a good price) but they have yet to put them to use. Hopefully, my video will be the inspiration they need to get their own outdoor sink set-up.

I'm curious to see how long the tap adapter mechanism will hold up. Sooner or later it has to break. But two years and tapping is good. Please be sure to let me know if/when your adapter gives up the spring (or whatever). Fortunately, they aren't too expensive and will be easy to replace.

I'm really impressed with the fact that you are butchering your own pigs (do I understand that correctly?). We raised our first two pigs last year and I considered butchering them but chickened out. Big difference between processing poultry and pigs! Where did you learn how to cut up a pig?

I've been going to write about our first experience raising pigs last year. It was a good experience. They were happy pigs. And we are enjoying the home-raised meat. But we killed them ourselves before taking them to the butcher. That was kind of brutal, being the first time and all.

As always, thanks for the comment.

Hi Clark—

I was surprised to see my essay at the Abbeville Institute web site. But pleased to see that they put it there. I'm a Northerner by birth (something I had no control over), but a Southerner at heart.

The best elements of "Southern tradition" need to be better understood and preserved. The agrarian ideal is among those best elements, and I appreciate what Abbeville Institute is doing.

Hi Herrick, over the last two years we have butchered about 55 turkeys and60 X Cross chickens. I call them my Frank Perdue flock. During each session, we do 12-15 at a time, that little toetapper gets turned off and on probably a couple hundred times.

When we are not doing that I have it mounted on the wood trim just outside the roll up barn door. it is connected to one of those Little Big Shot nozzles. They make a nice variable stream but are a pain it the Gluteus Maximus muscles because you have to screw it in or out to adjust. I just set it where I want it and leave it. Then it is just bang the tapper!

I have been involved with butchering pigs and cows since I was about 7 or 8. There was a long hiatus while in the USN, but when we got back here I took it up with a vengeance. Got my youngest son Kirk got interested and we both learned the finer points of parting out a large animal from the local Food stores butcher. He was an Army trained cook and butcher, so every cut had to be precise. It never used to bother me to put an animal down, but in the last few years now, I let someone else do the deed!

The boy really got interested in making sausage of all kinds, hot smoked, cold smoked, you name it he has probably made at least one batch. This year he started two full hindquarters on the way to becoming Proscuito(sp). It takes two years to fully cure in a temp and humidity

controlled space. He is using a small soda refrigerator the size of a small house one. After he got that one going he rolled up a big piece of what could have become bacon, and instead turned it into Pancetta. That only took 6-8 weeks to cure. And I made the guanciale, which is just bacon made out of the cheeks and jowls of the head. But it also hangs in the curing refrain. It is a dry cure withe just black pepper, salt, Instacure #2 and some thyme and rosemary. And it also has about an 8-12 week cure time. Remind me next fall if I'm still a viable entity and I'll send you a piece

I think I have taken up enough space for this time. Planting four types of spuds tomorrow! Best to you and Marlene, Everett

I am one of the people that bought a prototype and has yet to use it. I jumped at the chance to buy one even though I knew it would be a while before it got used. We have a lean-to we built on the back of our shop that is going to get set-up for our poultry butchering this year. We currently grow about 500 broilers and 35 turkeys a year that we butcher outside. The lean-to will be out-fitted with the Toe-tapper, a tub plucker that I built (styled after yours), and an automatic scalder I built (that I loosely styled after a Poultryman scalder).

-Matt the Farmer

Post a Comment