Dateline: 31 October 2013

|

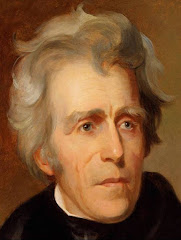

| Does anyone know what kind of apple this might be? |

This has been the best apple year I can remember, and my Whizbang cider-making equipment has gotten a real workout. Well over 150 gallons of fresh apple cider has been processed so far this fall with my grinder and press.

After loaning the equipment out to several neighbors, Marlene and I made 16 gallons of cider the weekend before last with Ken and Mary, two friends from high school (way back). Then, last weekend we made cider with our friends, Tim & Rose (from Finger Lakes Dexter Creamery), Ron (from Digging into Freedom's True Meaning), and Sandy (who doesn't have a blog or web site). It took us three hours on the back patio to press out 36 gallons, and it was a fun time. If you are looking for a way to make great family memories and have a good time with friends, I recommend Whizbang cider making It's a great community activity.

I'll be loaning the equipment to another friend next weekend so he can make cider with his family. But, before that, I needed to make cider with the rest of the apples we had. The apples were all free, either given to us or picked at a friend's place. In the pictures that follow I will show you how the Whizbang cidermaking system works. I was working alone for this final pressing, but that was fun too. The sun was shining and the temperatures were mild. I love to make cider!

Click on any of the following pictures

to see an enlarged view

The picture above shows the apples I used to make cider. There were at least four different varieties. A blend of different varieties makes for a better cider. The apples have been washed. That's the most tedious part of this whole procedure. The apples will be fed into the motorized Whizbang apple grinder. The apple mash will flow out and into the plastic pails.

The picture above shows the Whizbang cider press, which I designed and tell how to make in my book, Anyone Can Build a Whizbang Apple Grinder & Cider Press. That press may not have the charm of a traditional-looking cider press, but it is much more efficient at making cider, as you will see.

The above picture shows buckets of apple mash. You can see how the mash is white when it first comes out of the grinder, and soon oxidizes brown. The mash from all the apples I had filled five buckets, though I had to top them all off more than shown here in order to make it all fit.

The top of the Whizbang apple grinder has an apple corral around it, so you can fill the corral up and quickly feed the apples into the grinding mechanism. If the apples are big, you have to cut them so they fit into the 2-7/8" diameter opening. Cut apples self-grind in the chamber. If the apples are whole, you will need to use the "persuader" to push them down into the spinning mechanism. If the apples are big and whole, you may have to pound them down with the persuader. I didn't cut a single apple when I made cider for these pictures. I pushed and pounded them all and filled the five buckets in short time (I didn't keep track but I'm sure it took less than half an hour). Grinding apples with the Whizbang apple grinder is exciting.

The picture above requires some explanation. What you are looking at is a large stainless steel bowl on the seat of a patio chair. A "mash form" made from the bottom 3" of a plastic bucket is inside the bowl. I layer a 30" x 30" piece of cider pressing fabric over the form and bowl. Then I fill the form with mash. The corners of the fabric are gathered up and tied with string. This creates a mash bag....

The picture above shows a mash bag in the pressing tub. The white "pressing disc" will go into the tub on top of the bag. My Whizbang cidermaking system is different from every other home-scale cidermaking system in that I recommend making a stack of mash-filled bags separated by pressing discs. This is a more traditional approach to pressing cider. It is also an extremely efficient way to extract juice from the finely-ground apple mash. It is far more efficient that just filling a tub with mash and putting pressure to the top.

Please note in the above picture that a lot of juice is flowing into the catch-pan even before pressure is applied. It's not unusual to get more than a gallon of juice before even putting pressure to the tub.

There (above) you can see the tub all set up for pressing. In the tub are five bags of mash and four pressing discs, with a pressure plate on the top. I figure the tub will hold the mash from a bushel of apples.

When the 6-ton jack is fully extended (as shown in the picture above), I place two screwdrivers in the pressing shaft holes, under the cross beam, as you can see above. This holds the pressing shaft down while I release pressure on the jack and position some blocking under it, as you can see in this next picture...

There you can see that I placed three blocks under the jack and am reapplying pressure to the stack. A hydraulic jack is a wonderful tool for applying pressure. It's much faster to use than a traditional ACME screw. If the old-timers had hydraulic jacks, they would have used them. I should make it clear that a lot of pressure is not needed to press juice out of mash that is in bags, stacked between discs. Furthermore, when pressing bags of mash as shown here (and explained in my book), there is very little outside pressure on the tub. That means the tub doesn't have to be built with iron hoops and heavy wood slats.

My plan book tells how to make a traditional-style, wood-slat pressing tub but the tub shown in these pictures is simply a piece of 1/8" HDPE plastic. I made it last year to see how it would work, and it works just fine.

Seeing as I was making cider by myself, I didn't want to take the time to fill jugs, so I filled plastic pails. Most plastic pails you buy in a hardware store are made with food-grade plastic. You can tell by the triangle symbol, with a 2 in the center.

The pail above shows the amount of cider I got from a single pressing. It is at least 4 gallons, and that is typical when using the Whizbang apple grinder and pressing system. I've used other apple grinders (the turn-by-hand kind) and pressed tubs of the coarse mash (instead of layered bags full of fine mash) and the juice yield is not nearly as much.

The picture above shows the apple pomace (pomace is squeezed-out apple mash). You can see that it has been squashed flat and has very little juice in it.

The five pails of apple mash made three pails of cider, as you can see in the above picture. I covered them with plastic wrap and left them outside overnight. The next day I dipped out and poured the cider into plastic jugs for the freezer (filled part way to allow for expansion when freezing). Putting the cider in 5-gallon pails for awhile before transferring to smaller containers allows some sediment to settle.

In addition to freezing many gallons of cider, we are drinking cider every day, and we have seven gallon jars of cider vinegar fermenting. CLICK HERE to see and learn how we make cider vinegar.

I think the ideal situation for having apple cider to drink for several months out of the year would be to keep a supply of apples in cold storage, then simply press a bushel or two every couple of weeks. This would be better than pressing and trying to freeze a lot. In the winter months, jugs of cider will keep just fine outdoors.

Someday, Lord willing, I would like to build a retirement home for Marlene and I. It will have a full basement (something we don't have now) with a walk-out entrance. One section of the basement will be dedicated to year-round cider pressing. If the equipment is all set up, ready to use, out of the weather and cold, making cider would be no more work than, say, making an apple pie.

23 comments:

Thanks for sharing this.

Amanda

Matthew 6:33

Were your ears burning? We had our monthly meet up of the "Living Better With Less" group last night and I took along my two new books "How To Build a Whizbang Plucker" and "Whizbang Ideas for Gardeners" and there was a lot of stimulated and excited talk around the table. Posts about our latest meeting will follow soon and there will also be a review of your books. I'll give you a heads up soon. Take care, Tanya

Herrick:

You will love this story as much as I did!

http://sports.yahoo.com/news/ncaaf--how-one-small-texas-college-made-money-by-saying-no-to-football-065751785.html

DianeinTX

What kid of apple is that? It's a freckled apple, of course!

Great article. How are your apple trees doing? Mike W.

That is an interesting apple at the top of the post. It's very beautiful. This is a cider inspiring post.

Mick

cw—

I knew somebody would know it. Thanks! :-)

Mike—

My trees are doing surprisingly well. I say "surprisingly" because I didn't do anything with or to them after planting in the spring. Wehad an abundance of rain this year so I didn't have to water them at all, as is recommended with newly-planted trees. The fencing kept deer away. I didn't get them mulched as I wanted but there is time for that. My only concern for winter is to get a hardware cloth mouse guard around the tender trunks. Thanks for asking.

Mick—

That apple is truly beautiful. The tree it came from is in an old orchard on a friend's property.

I'd call the apple in the first picture a "Confetti Apple". What is it actually called? Sorry if you already mentioned it. I flew to the comments section before reading the rest of the blog - a "read the instructions if need be" kinda person, I guess. :-(

Sharon,

I like "confetti" for a name. No one has suggested a real name yet.

Hi Tanya,

I just checked out "living better with less group" on Google and at your blog. What a great idea. I'm pleased to know that my books are inspiring people so far away from where I live. Thanks for letting me know.

Dianein TX—

You are right. That is a great story and I thank you for letting me know about it!

Everyone who reads this blog will appreciate the article. Here is a Clickable Link

It was fun making cider with you folks. The apple variety pictured looks like an Orkney or maybe a Duchess of Oldenburg. Beautiful looking apple. My family has an apple tree that produces similar apples. It is the tallest and biggest apple tree I've ever seen. You have a great cider press! Keep up the good work.

Ron

Greetings Mr. Kimball from snowy Vermont! I have been reading your blog for many years and I find your ideas very inspiring. Do you think it would be possible to make a few dollars cider pressing for other people, or having the press set up in a permanent location and selling the cider? Is it risky selling a non-pasteurized cider? I think I should buy your book and maybe these questions are answered! I am a stay at home mom looking for ideas to bring in some money at home or with my land...I am also considering raising broilers and turkeys, but the season for that is short and the winters are long! Thanks for your time and best of luck!

Hello Anonymous person from snowy Vermont,

You would probably run into health department issues if you pressed cider for others. You could rent the equipment so others can make their own cider. But the equipment will take a beating.

One person who made the equipment told me he brought it to the farm market where he is a vendor and let people make their own cider for free right there at the market. He said it worked out really well. I can imagine it would be a popular thing, though not a direct money-making idea.

Someday I would like to have a Planet Whizbang showroom/mfg. facility and I thought it would be neat to have certain days in the fall when people could bring their apples and for a fee make their own cider on site. Sort of a on-site rental idea.

I'm sure there are ways to make money with the equipment but it would be seasonal and there is always the liability issue to consider.

Perhaps you could have reservation-only, fee-pay cider making parties, limited to a certain number of people and families, all working together for a few hours to make cider. That would be fun and it is one of those things that people would look forward to doing every year.

Best wishes.

Thanks for your response, I figured liability would be an issue...I'm sorry I forgot to sign my name, Robin! Cider making parties sound like fun though, but I guess the best way to have any sort of somewhat dependable income is to be diversified. I research a lot of ideas, it is a challenge to choose one and jump into it! Stay warm.

Where did you get the crates that are shown in the picture of whole apples before grinding?

They are used by bakeries when delivering bread. My wife used them years ago when she made bread for the farmer's market. They're stackable.

This blog doesn't appear to have had much activity in a while. So sorry if I missed the boat. I LOVE what you are doing with pressing all this juice and making delicious cider. I am only concerned about the buckets used. Do it best buckets...are they food safe? Something to look into. I suggest investing in KNOWN food safe containers to store the juices etc. That is all. Happy cider making...

Rich

Hi Rich—

Yes, the Do It Best buckets are made with a food-safe HDPE plastic. There is a symbol on the bottom of the bucket that indicates this, and I provide information about it in my Whizbang cider plan book. Most of the standard HDPE pails you can get in the stores are food-safe HDPE. But check the symbol to be sure. (there is information about this on the internet too)

Does your book have directions on how to make the plastic pressing bucket with all the holes along with how to make the pressing plates? Are there a lot of angles to cut when making this system? I tend to muff up when to many angles are needed. I love making cider and would love to start pressing my own.

Just a Guy—

There are two angles that need to be cut, one on the end of each legs. They needn't be perfect for the system to work, but I make it clear in the book exactly how to measure the angles before cutting.

The book tells how to make a traditional pressing tub, and then under the heading of "Other Tubs" I mention using a plastic pail and I go into less detail about that option because it's less involved and more intuitive (just drill a lot of holes in the bucket).

If you haven't yet watched my two YouTube videos about Whizbang cicermaking, you need to do that. The videos show the process and the tools very clearly. Here are the links...

Whizbang Cider Part 1

Whizbang Cider Part 2

Herrick... I bought your book and am gathering parts and materials to build this spring/ summer. The Whizbang website that no longer exists... I thought I read somewhere on there before that you recommend the badger 5xp disposal unit however your book mentions the badger is not ideal because of galvanized steel internals. Also I thought there was additional information about some units making the mash too thin. Do you have a #1 recommended unit that works best? I have acquired a 3/4 hp farm duty motor that spins at 1800 rpm with the 5/8" coupling.

Thanks

-tim

Hi Tim,

I was unable to renew the web site domain. Very discouraging. Fortunately, that was the only domain I bought through Google. I have remade most of the WhizbangCider.com web site at this link...

http://whizbangcider2.blogspot.com/

I think your question about the disposal to use is there, on the sidebar.

Best wishes,

Herrick Kimball

Post a Comment