Dateline: 2 August 2014

|

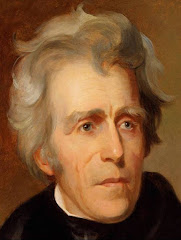

| One of the HDPE pressure plates I make for the cider pressing system I developed. A surprising amount of work goes into making these! (click the picture for an enlarged view) |

Back in 2009 I published the book, Anyone Can Build a Whizbang Apple Grinder & Cider Press and I created the Whizbang Cider web site to promote my improved home-scale cider making system. The book has sold well and feedback has been gratifying. I recently made the plans available in PDF format for $14.95, which is $7 less than the paperback book. Click Here for PDF Information.

One of my business strategies is to create a how-to book and then sell items that help readers make what the book tells them how to make. For example, I wrote a book about how to make a chicken plucker and I sell some of the parts needed to make a chicken plucker. I make far more money selling chicken plucker parts, and processing accessories (e.g., poultry shrink bags), than I do selling plucker plan books. So it is that I have sold various cider press parts for several years now.

|

| Bottom view of the pressure plate. Stainless steel screws are used to hold the "curb" on the top of the plate in place. |

However, I decided earlier this year to stop making the HDPE plastic cider press parts I've been making and selling. Although the HDPE parts have been precision-cut for me by a computerized machine, I have had to put a lot of hand work into sanding and assembling the parts. The pressure plates, in particular, have been very time consuming to make. Besides that, hand-sanding so many parts has been hard on my median nerve, leading to carpel tunnel issues.

I had a small quantity of the plastic pieces in stock and made it my goal to get them assembled and ready to ship by the end of July, which was two days ago. The last of the HDPE parts are now available at WhizbangCider.com

On the one hand, I hate to stop selling something that I've been making and selling for several years. It's very satisfying to make a product and sell it. But, on the other hand, I'm relieved to have the last of these parts done. I will be able to focus on making other Whizbang products, like Classic American clothespins.

I will still sell high-quality cider press fabric, but the HDPE parts will soon (very soon) no longer be available from me anymore. Last call….

|

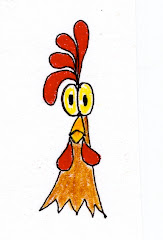

| Some finished pressure plates on the shelf, ready to ship. The pressing discs on the shelf above are easier to make but still a chore. I will be out of the pressing discs before the pressure plates. |

8 comments:

One of the guys who run our new brewery was telling me how he bought one of your cider presses a while back and how it worked good. My claim to fame was that I follow your blog!

Mr. Kimball, please save a set of parts for me. I will put an order in immediately. Thank you for telling us and I have to say one more time, with great gusto, your instructional manuals are superior to anything I have ever come across.

Looking forward to making cider!!!

Pam

Sunnybrook—

It's always nice to get a good report. Thanks for that.

I know from experience that my press and grinder far surpasses the traditional-style cider making equipment that others sell. The Whizbang system is faster, easier, more efficient, and therefore a whole lot more satisfying to use.

However, I don't do any magazine advertising or other marketing (beyond my web sites) so my equipment doesn't get the exposure and sales that the other equipment does. Nevertheless, the word seems to be spreading slowly and surely in cider making circles. This is especially the case when someone who has experience with the traditional ACME screw presses sees the difference.

Pam—

Thank you. I have just removed the order button for the set of 4 pressing discs on my web site. Between yesterday and today I have sold all that I have. BUT I've set aside the last set for you. Whenever you want to order, just send me an e-mail and I'll let you know how you can get the pressing discs with the order button now gone.

hckimball@bci.net

Mr. Kimball,

Have you considered moving your parts to Thingiverse? (https://www.thingiverse.com/) They provide CNC cutting and machining services and then drop ship. You set the price for the parts, naturally above their costs. It would seem to be a suitable alternative to dropping a product.

Besides, I think most anyone who has ordered your plans would consider doing the sanding just part of the whole process. Everyone wins so to speak.

Best Wishes.

Please don't take these off the market! I've been dreaming for 7 years of doing this... I'm so close! Ditto what Tucane said... I have plans to build and buy parts in the future, but I just planted my tree's two months back and I'm not in a position to spend any more money right now! You liked my idea of letting people assemble their own clothes pins... can't you just ship rough parts and let me sand and assemble all of the cider press parts?

Tucanae Services—

I've never heard of thingiverse. Thanks for the link. I'll check it out.

Clinton—

You can still purchase HDPE plastic and make the parts yourself. The material can be worked with common woodworking tools.

But you have me thinking. Maybe it would work to supply the basic parts, as they come to me from the cmc machine, and provide a step-by-step photo tutorial showing how to get them finished off.

Actually, I was thinking of this yesterday, when I discovered that I had parts tucked away for making 25 more pressure plates. (My shop is so crammed full of stuff that I lose track of things).

Perhaps I'll get those together in a kit, with the stainless steel screws and so on. In fact, I'm pretty sure I will do that, though I don't know if I will do it for this year.

Thanks for the suggestion. I'll start rethinking my approach with DIY in mind.

Hello Mr Kimball, I sent an email but it came back as "server unavailable for too long" or some such nonsense. Please let me know if you don't receive it today.

Thanks,

Pam

If you're checking HDPE Sheet price in Chennai, this link offers detailed rates and material specifications. Whether you need sheets for construction, lining, or industrial use, the pricing is competitive and the material quality is dependable for both bulk and small orders.

Post a Comment